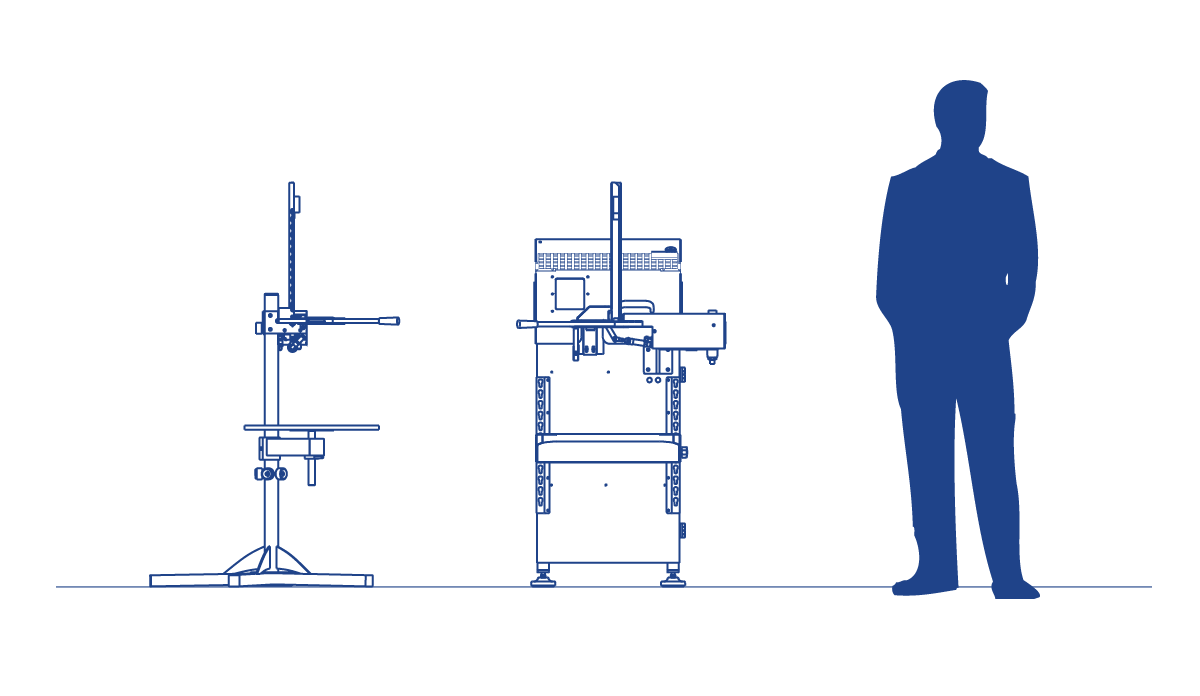

The manual bag closer allows the sealing and labeling of shellfish or other products in bags up to 25 kg in weight using aluminium clips of various sizes. The best solution for every kind of need in the shellfish packing sector, the manual bag closer is a machine dedicated both to small productions (fisheries and traders) and to the biggest shellfish dispatch centers.  In fact the machine offers the possibility to close and label bags of big volume, even with products that, because of their characteristics, is not possible to pack with automatic machines.

In fact the machine offers the possibility to close and label bags of big volume, even with products that, because of their characteristics, is not possible to pack with automatic machines.

The bag closer is available in many models, to work with clips of 2.5, 3 or 4 mm of wire diameter. The machine can also be used with clips of different length, in order to close bags of different thickness.

The materials utilized in the construction of this machine, as for every other machinery built by our company, are especially dedicated to the use in the marine environment and in the harshest conditions: the structure of the machine is made of Aisi 316L stainless steel and plastic material suitable for the contact with food, all in line with the European Community regulations for the food processing sector.

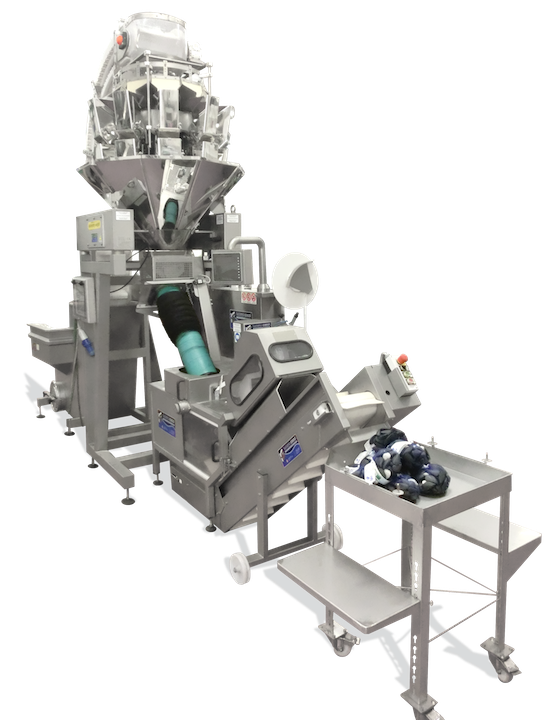

The manual bag closer can be integrated with a labeling and stamping system that allows to apply food-grade plastic straps to the bags. These "ribbon" labels are pre-printed on one side with all the information relating to the company and the packaged product, while on the back it is possible to stamp the date, batch number or other short variable data using a pneumatic stamping / punching system. This type of labeling is suitable for those who work only one or two types of products and do not have access to stable power supply sources, such as floating shellfish shipping centers (on board fishing boats).

The manual bag closer can be integrated with a labeling and stamping system that allows to apply food-grade plastic straps to the bags. These "ribbon" labels are pre-printed on one side with all the information relating to the company and the packaged product, while on the back it is possible to stamp the date, batch number or other short variable data using a pneumatic stamping / punching system. This type of labeling is suitable for those who work only one or two types of products and do not have access to stable power supply sources, such as floating shellfish shipping centers (on board fishing boats). A stainless steel cover protects the printer, that is an industrial model with a solid structure made of metal and high resistance plastic material, ready to be used in the harshest environements. The bag closer cut the printed label and seal it firmly on the bag together with the aluminium clip, all in one operation.

A stainless steel cover protects the printer, that is an industrial model with a solid structure made of metal and high resistance plastic material, ready to be used in the harshest environements. The bag closer cut the printed label and seal it firmly on the bag together with the aluminium clip, all in one operation.